CRM, the collective research centre for metallurgy in Liège, specialises in the recycling of steel, aluminium and zinc waste streams. It wants to assist companies in the field of Research & Development and technological solutions. CRM works with residual flows that can be both post-industrial and post-consumer in origin.

Ahmed Rassili, business developer at the CRM group, says that recycling the residual ‘post-consumer’ stream is a particularly complex process. A lot of metal products like aluminum packaging are definitely not designed to recycle.

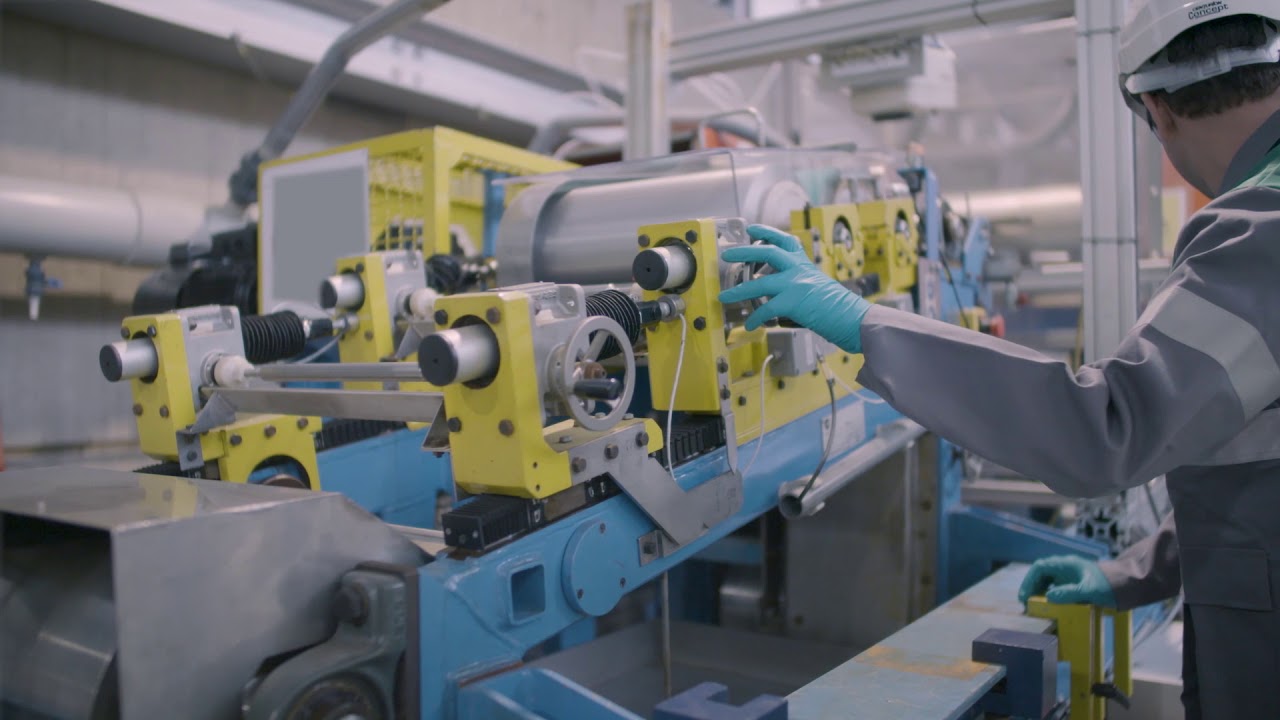

“In one aluminium can, for example, there are different types of aluminium that need to be separated before they can be recycled,” says Ahmed Rassili. In the CRM lab, installations are built to enable this separation process of the materials.

“In one aluminium can there are different types of aluminium that need to be separated before they can be recycled”

Ahmed Rassili – Business developer CRM group

For example, the residual flow ‘post-industrial’ indicates metal slag that originates in the furnaces of large steel companies such as ArcelorMittal. CRM developed technology to recycle the metal slag into high-quality materials.

The CRM group is a collective research centre and has been active since 1948. The two largest steel producers in the world, ArcelorMittal and Tata Steel, are also the hub in this centre. First of all, it develops technological solutions to enable the qualitative recycling of metals. Crm wants to be the pioneer for the transition from linear to circular metal industry.