Fruit and vegetable growers widely use small wooden boxes for their transport. Boxes that are only used two or three times and, because they are made of different materials, are burned rather than recycled. A residual flow that can be tackled? This is also the conviction of BelOrta, which wants to work on a solution together with Wanderful.stream.

The BelOrta cooperative has existed for over 70 years and during that time many conventions have crept in, for example, in the way they package and transport fruit and vegetables. Transport from grower to auction, or from auction to retailers/restaurants, export, … The company’s largest residual flows are therefore to be found in this area. For example, the simple wooden fruit crates with apples and pears. These fruit boxes combine three different materials: two different types of wood, namely untreated wood for the sides with a base of hardboard (treated wood) and held together with galvanised wire or staples.

“The fruit crates consist of a combination of untreated wood with hardboard bottom and staples. Difficult to recycle and therefore it is simply burnt. It can be done better and more sustainably.”

Tom Janssen

– Wanderful.stream

UCLL Research & Development

EUROPEAN MARKET LEADER

The crates are reused at most two to three times before they end up as waste at recycling centres. There, the very mixed composition creates a problem, so the coffins are simply burned. Good for energy valorisation, but it could be better. This is also the conviction of BelOrta, with its 1,350 affiliated growers the largest cooperative fruit and vegetable auction in Belgium (merger of Mechelse Veilingen, Coöbra and Veiling Borglon) and as European market leader they have a turnover of 400 million euros. Millions of fruit and vegetables are grown and traded each year, and to be clear: BelOrta does not produce these fruit boxes itself, but it does want to take the lead in the field of sustainability and circularity.

“With BelOrta we try to take a lot of steps ourselves in the field of sustainability”, says Wim Hubrechts, coordinator sustainability BelOrta, “but when we were introduced to Wanderful.stream, we put it to the test by looking together at the Borgloon site to see which flows could still be improved. The problem of the limited shelf life of the crates and their processing still leaves a lot of room for innovation.” With a view to material and use, but also to whether the system behind these boxes could be improved.

LOW DENSITY

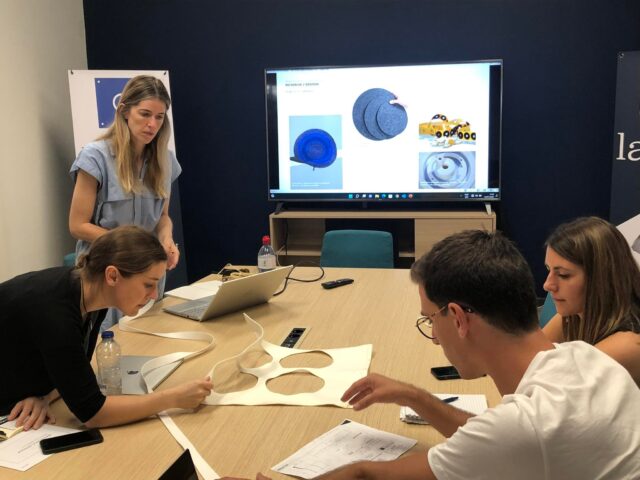

This was already on the table during the boot camp session in the autumn of 2020, when designer Frederik Deschuytter and a team of students came up with the concept of ‘Low density fibre crates’. This new, reusable, lightweight fruit/vegetable box could be made entirely of one and the same sheet material, namely Low Density Fibre. Using CNC or laser, these wooden elements could be optimally cut out and fitted with a click system so that these boxes have the same properties as their predecessors, but are much more durable, easier to repair and at the end-of-life easier to recycle.

The potential thus uncovered convinced Wanderful.stream and its experts to investigate this concept further in a fully-fledged innovation project. However, in order to avoid the transition from Bootcamp concept to innovation path, the premise was re-examined. What can be changed or improved about these boxes in order to achieve a sustainable circular solution for the whole sector.

“With BelOrta, we naturally

have been focusing on sustainability for some time.

We want to set a good example

for the whole sector.”

Wim Hubrechts

– coordinator sustainability BelOrta

Under the supervision of Tom Janssen, a team was put together in which the technological experts within UCLL Research & Development work together with designer Frederik Boonen (Boonen Design Studio) and Birgitt Deckers (Studio Planeet) as business developer. Ditzelfde team wil overigens ook een andere reststroom van BelOrta aanpakken, namelijk het paraffine papier dat dient als bescherming tijdens het transport. Ook deze reststroom wordt in een apart innovatietraject aangepakt om de paraffine te valoriseren. You can read more about that in this article.

During the Community Event on 3 July 2020, moderator Xavier Taveirne had a deeper discussion with the above actors. You can watch it again here.